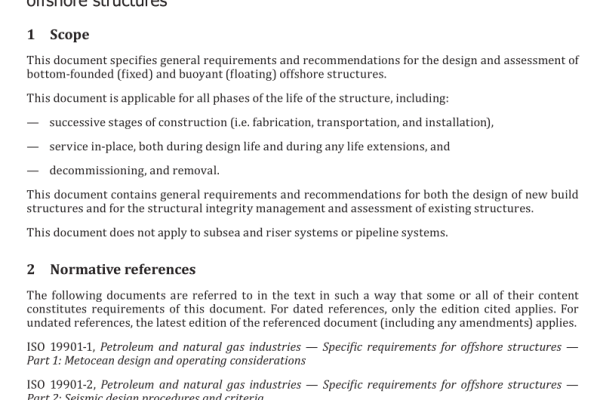

AS ISO 19900:2022 pdf download Petroleum and natural gas industries — General requirements for offshore structures

3.7

basic variable

variable representing physical quantities which characterize actions (3.3) and environmental

influences, geometric quantities, or material properties including soil properties

Note 1 to entry: Basic variables are typically uncertain random variables or random processes used in the

calculation or assessment of representative values of actions or resistance.

3.8

calibration

process used to determine and optimize partial factors using structural reliability analysis (3.52) and target reliabilities

3.9

characteristic value

value assigned to a basic variable (3.7) with a prescribed probability

Note 1 to entry: In some design/assessment situations, a variable can have two characteristic values, an upper value and a lower value.

3.10

conductor

tubular pipe set into the ground to provide the initial stable structural foundation for setting the surface casing and protecting the internal well string from metocean actions

Note 1 to entry: The conductor provides lateral and, in some cases, axial support, enables circulation of drilling fluid, and guides the drill string to facilitate setting of the surface casing.

3.11

decommissioning

process of shutting down a platform (3.37) enabling preparations for cleaning, dismantling and/or removal from location at the end of total service life (3.18)

3.12

design resistance

resistance limit calculated using factored representative values (3.40) of basic variables (3.7) or from factored expressions based on unfactored representative values (3.40) of basic variables (3.7)

EXAMPLE Examples of basic variables relevant to resistance are material properties.

3.13

design service life

planned period for which a structure (3.53) is used for its intended purpose with anticipated maintenance, but without substantial repair being necessary

3.14

design value

value derived from the representative value (3.40) for use in limit state verification (3.32)

Note 1 to entry: Design values can be different in different design/assessment situations due to different partial factors.

3.15

design/assessment criteria

quantitative formulations describing the conditions to be fulfilled for each design/assessment situation (3.16)

3.16

design/assessment situation

set of physical conditions for which the structure (3.53) or its components are verified

3.17

deterioration

process that adversely affects structural integrity (3.50) over time

Note 1 to entry: Deterioration can be caused by naturally occurring chemical, physical, or biological actions including corrosion, by severe environmental actions, by incidents and accidental actions, by repeated actions such as those causing fatigue, by wear due to use, and by improper operation and maintenance of the structure.

3.18

total service life

design service life (3.13) plus any subsequent operational life extension period(s)

3.19

durability

ability of a structure (3.53) or structural component (3.49) to maintain its function throughout its total service life (3.18)

3.20

exposure level

classification system used to establish relevant criteria for a structure (3.53) based on consequences of failure

3.21

extreme environmental event

environmental hazardous event (3.27) typically having probability of occurrence of 10 −2 per annum (1 in 100 years)

3.22

fit-for-service

fulfilling defined structural integrity (3.50) and performance (3.36) requirements

Note 1 to entry: A structure not meeting all the specific provisions can be fit-for-service, provided it does not cause unacceptable risk to life-safety or the environment.

AS ISO 19900:2022 pdf download