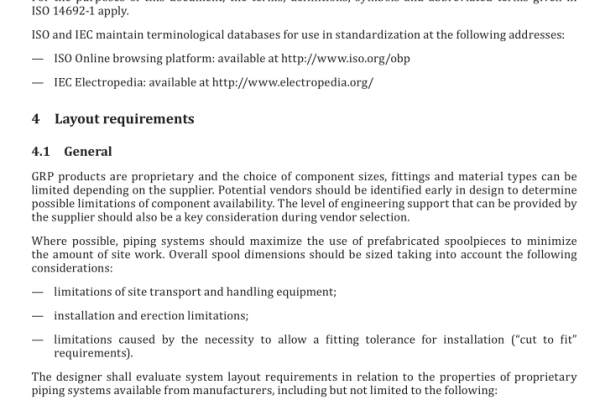

AS ISO 14692.3:2022 pdf download Petroleum and natural gas industries — Glass-reinforced plastics (GRP) piping Part 3: System design

Small pipe branches (e.g. instrument and venting lines), which are susceptible to shear damage, should be designed with reinforcing gussets to reduce vulnerability. Impact shielding, if required, should be designed to protect the piping together with any fire-protective coating.

4.5.3 Dynamic excitation and interaction with adjacent equipment and piping The designer shall give consideration to the relative movement of fittings, which can cause the GRP piping to become overstressed. Where required, consideration shall be given to the use of flexible fittings. The designer should ensure that vibration due to the different dynamic response of GRP (as compared with carbon steel piping systems) does not cause wear at supports or overstress in branch lines. The designer should ensure that the GRP piping is adequately supported to resist shock loads that can be caused by transient pressure pulses, e.g. operation of pressure safety valves, valve closure etc. Reference [8] provides further guidance.

4.5.4 Exposure to light and ultraviolet radiation Where GRP piping is exposed to the sun, the designer shall consider whether additional ultra violet radiation (UV) protection is required to prevent surface degradation of the resin. If the GRP is a translucent material, the designer should consider the need to paint the outside to prevent possible algae growth in slow-moving water within the pipe.

4.5.5 Low temperatures and requirements for insulation The designer shall consider the effects of low temperatures on the properties of the pipe material, for example, the effect of freeze/thaw.

For liquid service, the designer should particular pay attention to the freezing point of the internal liquid. For completely filled lines, solidification of the internal fluid can cause an expansion of the liquid volume, which can cause the GRP piping to crack or fail. For water service, the volumetric expansion during solidification or freezing is more than sufficient to cause the GRP piping to fail. The pipe may need to be insulated and/or fitted with electrical surface heating to prevent freezing in cold weather or to maintain the flow of viscous fluids. The designer shall give consideration to:

a) additional loading due to mass and increased cross-sectional area of the insulation;

b) ensuring that electrical surface heating does not raise the pipe temperature above its rated temperature.

Heat tracing should be spirally wound onto GRP piping in order to distribute the heat evenly round the pipe wall. Heat distribution can be improved if aluminium foil is first wrapped around the pipe.

4.6 Fire and blast

The effect of a fire event (including blast) on the layout requirements shall be considered. The possible events to be considered in the layout design of a GRP piping system intended to function in a fire include the following:

a) blast overpressure, drag forces and projectile impacts;

b) fire protection of joints and supports;

c) interface with metal fixtures;

d) formation of steam traps in piping containing stagnant water, which would reduce the conduction of heat away by water;

e) jet fire;

AS ISO 14692.3:2022 pdf download