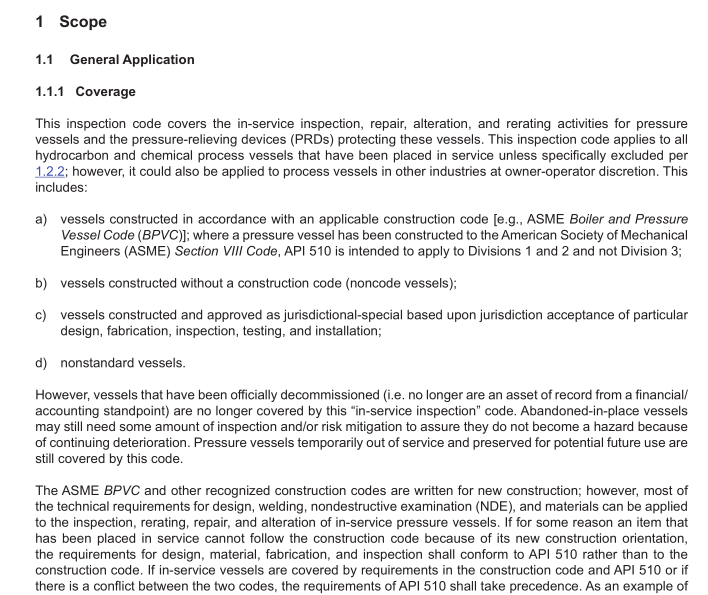

API 510-2022 pdf download Pressure Vessel Inspection Code: In-service Inspection, Rating, Repair, and Alteration

3.1.6 authorized pressure vessel inspector An employee of an authorized inspection agency who is qualifed and certifed to perform inspections under this inspection code, including Annex B. Whenever the term “inspector” is used in API 510, it refers to an authorized pressure vessel inspector.

3.1.7 condition-monitoring location CML A designated area on pressure vessels where periodic examinations are conducted to directly assess and monitor the condition of the vessel using a variety of examination methods and techniques based on damage mechanism susceptibility. CMLs may contain one or more examination points and can be a single small area on a pressure vessel, e.g., a 50 mm (2 in.) diameter spot or plane through a section of a nozzle where recording points exist in all four quadrants of the plane. NOTE CMLs include but are not limited to what were previously called thickness-monitoring locations (TMLs).

3.1.8 construction code The code or standard to which a vessel was originally built, such as API/ASME (now out of date), ASME BPVC, state special/non-ASME, or any other construction code to which the vessel was built.

3.1.9 controlled-deposition welding CDW Any welding technique used to obtain controlled grain refnement and tempering of the underlying heat-afected zone in the base metal. Various controlled-deposition techniques, such as temper bead (tempering of the layer below the current bead being deposited) and half bead (requiring removal of one-half of the frst layer), are included (see 8.6).

3.1.10 corrosion allowance Additional material thickness available to allow for metal loss during the service life of the vessel component.

3.1.11 corrosion rate The rate of metal loss due to erosion, erosion/corrosion, and/or the chemical reaction(s) with the environment, either internal and/or external.

3.1.12 corrosion specialist A person acceptable to the owner-operator, who is knowledgeable and experienced in the specifc process chemistries, damage mechanisms, materials selection, corrosion mitigation methods, corrosion-monitoring techniques, and their impact on equipment.

3.1.13 corrosion? under? freproofng CUF Corrosion of piping, pressure vessels, and structural components resulting from water trapped under freproofng.

3.1.14 corrosion under insulation CUI External corrosion of piping, pressure vessels, and structural components resulting from water trapped under insulation. External chloride stress corrosion cracking (ECSCC) of austenitic and duplex stainless steel under insulation is also classifed as CUI damage.

API 510-2022 pdf download